Heatwave has recently become one of the most talked about topics in the world. It’s high time we take some measures to fight it. Being the leading furniture brand in Bangladesh, HATIL started taking responsibility a long time ago. Here’s how:

Collecting Raw Materials from Sustainable Sources

We collect wood from FSC-certified forests only. The Forest Stewardship Council (FSC) is the world’s most respected non-governmental organization that gives certifications to forests that are managed responsibly. An FSC-certified forest wood means the forest is taken care of by experts to preserve biological diversity and benefit the lives of local people and workers while ensuring economic sustainability. They follow strict rules and therefore are trusted worldwide.

It means HATIL does not collect wood from trees that are less in number on earth. It also means that we only choose the best quality woods as raw materials from the best natural sources.

Using State-of-the-Art Technology in the Production Process

Firstly, we use a UV lacquer machine to varnish our furniture. Therefore, the furniture gets added protection from the UV rays and looks silky. HATIL furniture is popular for its longevity and durability.

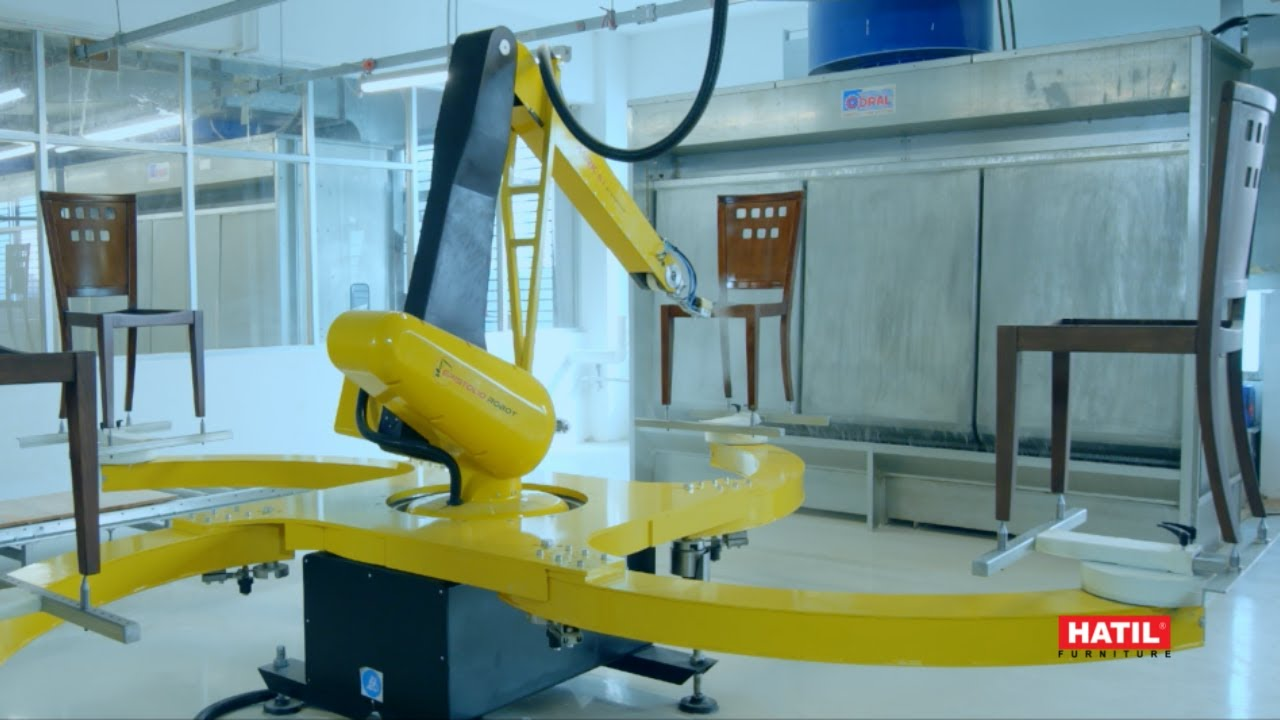

Secondly, we use robots in the lacquering process. The chemicals used in lacquering are harmful to health. Using robots keeps our workers safe from health hazards and ensures zero mistakes during the process. Moreover, a robot can complete a lacquering process 3-4 times quicker than a human which helps us run the factories for a lesser time and produce less pollution.

Thirdly, all the wood dust produced during the manufacturing process is collected through an automated central dust collection machine. Thus, the dust cannot get inside the workers’ lungs or get mixed in the air. Which means we are taking care of both our workers and nature simultaneously.

Turning Industrial Waste into Renewable Energy

Our production process creates three main types of industrial wastes- wood dust, wood offcuts, and fabric & foam leftovers. Our central dust collection machine transforms all the collected wood dust into briquettes or wood pellets. We later use them as fuel.

About the wood offcuts, we do not throw them away. Rather, we efficiently recycle these unusable wood pieces and produce particle boards from them.

The fabric and foams that remain as wastes are used to produce rebounded mattresses.

We also run an eco-friendly solar project in our factory. And this project is capable of generating 2.67 MW of renewable energy that reduces our dependence on conventional fuel from the National Grid. Thus, we have been contributing to fulfill the country’s sustainable energy demands.

We believe that these initiatives have added significant value to safeguarding the environment. Recycling wastes to generate renewable energy is a complex and expensive procedure. Also, global temperature is not going to go down overnight. It will take time but it is possible if all the factories and production facilities around the country show the same responsible behavior. Any of our needs including furniture should not cost us the health and well-being of the future generation.

So, are you in for achieving this goal together?